Every year in the United States, over 400 people lose their lives to unintentional carbon monoxide (CO) poisoning. Issues with fuel-burning appliances like furnaces heavily contribute to these tragic accidents.

How can a furnace pose this danger? It usually boils down to the existence of a cracked heat exchanger.

What is a Furnace Heat Exchanger?

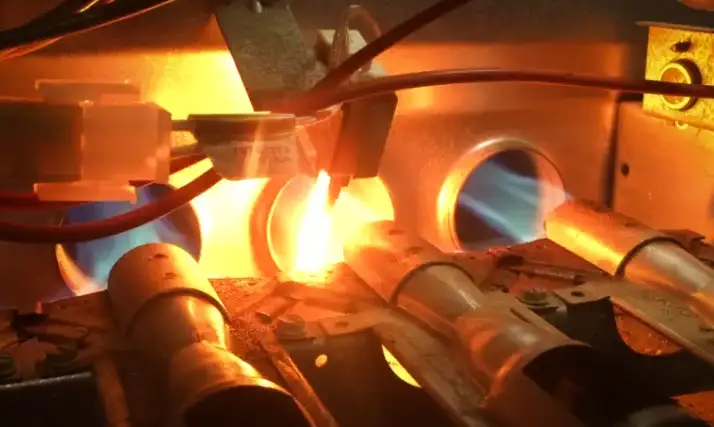

A furnace heat exchanger plays a pivotal role in maintaining indoor comfort during the cold season. Heat exchangers are designed to transfer heat from the burning fuel while preventing the mixing of exhaust gases with the indoor air in your home.

Heat exchangers come in various types, two of the most common being shell and tube heat exchangers and plate heat exchangers. Both facilitate the transfer of heat between two fluids, typically at different temperatures.

Shell and tube heat exchangers are favored for their simplicity, flexibility, and cost-effectiveness. However, plate heat exchangers offer a more compact design with higher temperature capabilities.

A cracked heat exchanger can allow exhaust gases, such as carbon monoxide, to leak into your living space. Carbon monoxide (CO) is an odorless, colorless gas that can result in serious health problems, including fatalities.

Common Causes of Heat Exchanger Cracks

Understanding the factors that lead to heat exchanger cracks is crucial for preventing these hazardous situations:

- Frequent Temperature Fluctuations: The constant expansion and contraction of the metal during heating and cooling cycles can gradually weaken the heat exchanger.

- Inadequate Furnace Maintenance: Regular furnace maintenance provided by reputable service providers is essential. Without proper upkeep, dust, moisture, and heat can contribute to rust and corrosion, weakening the metal and potentially causing cracks. Overheating, often triggered by a dirty air filter, is another vital reason for consistent maintenance.

- Age: Heat exchangers have a typical lifespan of around 15 to 18 years. If yours is older, it’s advisable to consider replacement to ensure safety.

- Improper Installation: Incorrect installation practices can lead to cracks. Factors such as the Start-up Temperature Rise setting must be appropriately adjusted for the local elevation to prevent issues.

- Manufacturing Defects: Occasionally, heat exchangers may fail due to manufacturing flaws or production issues.

Varieties of Heat Exchanger Cracks

Identifying different types of cracks that can occur in heat exchangers is essential for assessment and safety:

- Partial (Hairline) Cracks: Initially, these cracks may not penetrate the total thickness of the metal but can expand over time due to the continuous heating and cooling cycles.

- Small (Through) Cracks: While these cracks may not be immediately visible, they can be hazardous if exhaust gases start infiltrating your home. Professional inspection is critical in such cases.

- Large (Full) Cracks: These cracks are substantial and clearly visible, posing an imminent danger that requires immediate heat exchanger replacement.

Detecting a Cracked Heat Exchanger

Indications that your furnace’s heat exchanger may be cracked include:

- Accumulation of soot

- Unusual, unpleasant odors resembling formaldehyde

- The presence of water under the furnace

- Household members experience symptoms like dizziness, nausea, sickness, or disorientation.

- Activation of carbon monoxide detectors within your home

- Corrosion or visible cracks on other furnace components

- A visible yellow or orange flame when the furnace is operating

If you notice any of the above signs in your home, you should take them as potential indicators that you have a problem with your heat exchanger. Immediately call Wright’s Air and we can offer a definitive diagnosis that involves visually inspecting the heat exchanger and addressing the danger.

Preventing Heat Exchanger Cracks

The best way to protect your home and family from the dangers of cracked heat exchangers is to enroll in one of our Comfort Assurance Plans. Regular inspections are essential for identifying cracks and other potential issues that may jeopardize your safety. During our inspection, if we detect a cracked heat exchanger, we will explain how to remedy the problem.

In addition to preventive maintenance, we recommend the following steps to help prevent this issue with your furnace:

- Make sure your furnace is sized correctly for the area it is tasked with heating

- Ensure the furnace is properly installed

- Frequently change your furnace filters.

- Maintain cleanliness in the utility room

- Make sure the Start-up Temperature Rise is appropriately configured for your local elevation

The Cost of Repair

Repairing a cracked heat exchanger is generally not a feasible option. Replacement costs can often amount to several thousand dollars, with even warranty-covered replacements incurring high labor costs due to the necessity of disassembling the entire furnace unit.

Given the significant expenses involved, furnace replacement is frequently recommended, especially for units exceeding ten years of age.

Final Thoughts

A cracked heat exchanger is a serious safety hazard that can lead to carbon monoxide poisoning and potentially fatal consequences. Proactive maintenance, regular professional inspections, and prompt resolution of potential issues are essential to ensuring the safety and efficiency of your furnace and heat exchanger.

At Wright’s Air, we are committed to the safety and security of our valued customers. As always, we work hard to keep you informed of ways to enhance the life, efficiency and saftey of the HVAC system in your home. Call us at (903) 455-5662 if you would like us to stop by and see how we can help safeguard your home and family from the perils of cracked furnace heat exchangers.